1 / 7

Sample Preparation

- Pulsed-laser thin film deposition facility

- RF sputtering facility

- Czochralski crystal growth facility

- Arc-melting facility

- Various tube and box furnaces

- RF furnace

2/ 7

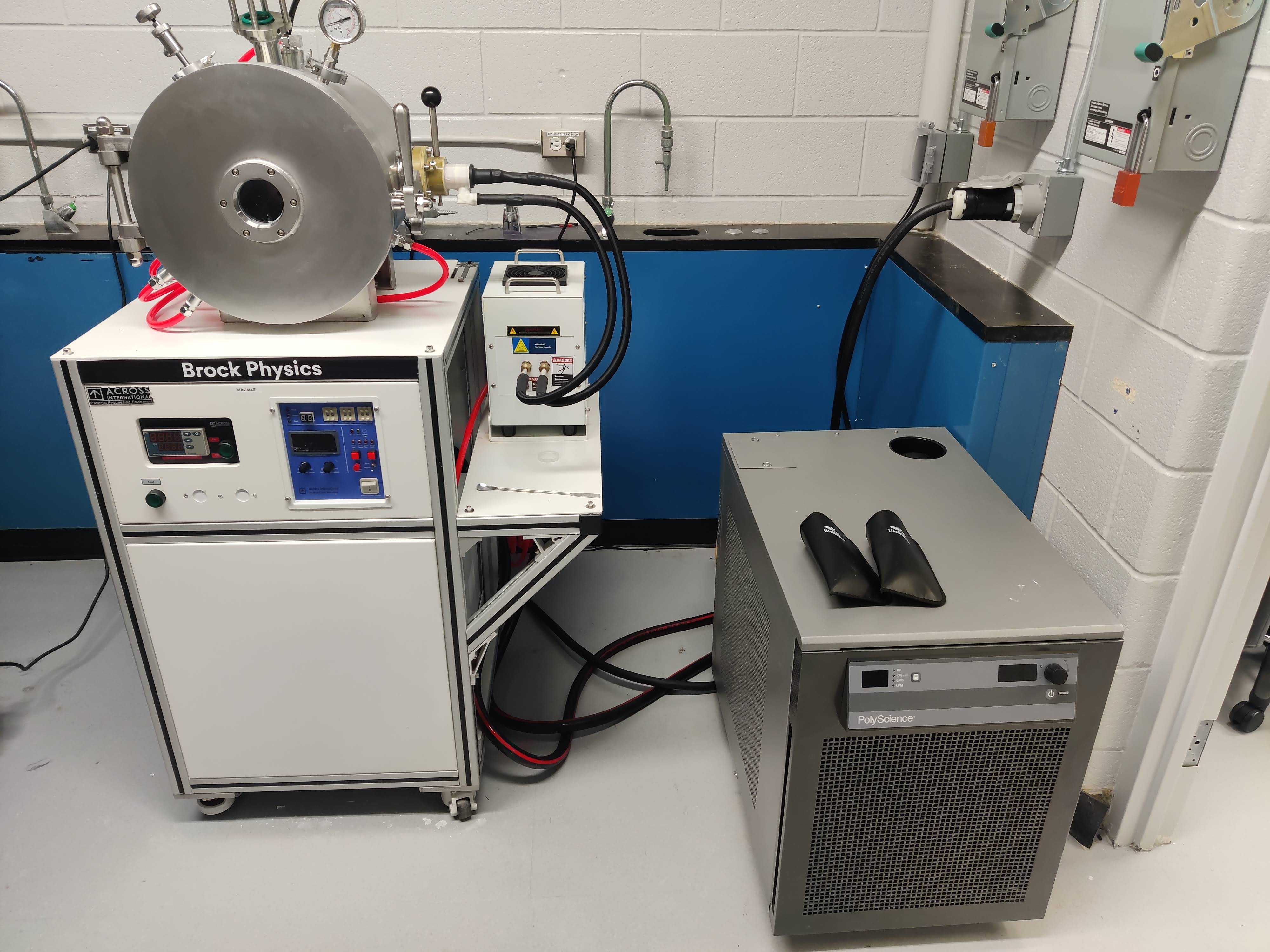

Melt Casting Furnace

- Prof. Hester's melt casting furnace for creating new materials with applications in quantum computing and magnetocaloric cooling. This furnace can melt most materials in a matter of minutes using induction heating.

- Checkout a video of the furnace in use here

3 / 7

Materials' characterization

- Rigaku SmartLab X-ray diffractometer with a 2D digital detector

- Hitachi SU5000 FE scanning electron microscope with Deben STEM and Oxford XRF detectors

- Custom IR labs Helium-3 cryostat (DC resistivity/AC susceptibility)

- EDS elemental analysis

- Bomem Michelson interfereometer (200-5000 cm-1)

- Various continuous flow and closed-cycle cryostats

4 / 7

Materials' measurement systems

- SQUID Magnetometer

- Quantum Design Magnetic Property Measurement System (MPMS)

- Quantum Design Physical Property Measurement System (PPMS)

- Closed-loop liquid Helium cooling

- Specific heat, susceptibilty- and resistivity-measuring instruments for a wide temperature range and under pressure

5 / 7

Optical and NMR spectroscopy

- Custom IR labs Helium-3 cryostat (reflectance)

- Sciencetech Martin-Puplitt type interferometer (5-200 cm-1)

- Bruker IFS66V/S Interferometer (20-40000 cm-1)

- Jarell-Ash double grating spectrometer for Raman spectroscopy

- Solid-state multi-channel NMR spectrometer with a 7T superconducting widebore magnet

6 / 7

Raman spectroscopy

- Raman spectrometer with a cryogenic temperature-controlled stage

7 / 7

Computer facilities

- Up-to-date and well-supported general-purpose computing throughout campus

- Membership in SHARCnet for large-scale parallel computing

- A large departmental Linux workstation group (80+ nodes), universal access to all faculty and students